Working principle:

Working principle:

Hot air from the inlet tube at the appropriate jet speed from the bottom of the Drying machine into the mixing crushing drying room, the material has a strong shear, blowing, rotating, so the material by centrifugal, shear, collision, friction and micro-granulation , Enhanced mass transfer heat transfer. At the bottom of the Drying machine, the larger and heavier particles are mechanically crushed under the action of a stirrer. The moisture content is low and the particles with smaller particle size are entrained by the rotating air stream and are further dried during the rising process. Phase rotation, solid phase inertia is greater than the gas phase, solid gas between the two relatively large speed, strengthen the two-phase mass transfer heat transfer, so the machine production of high strength.

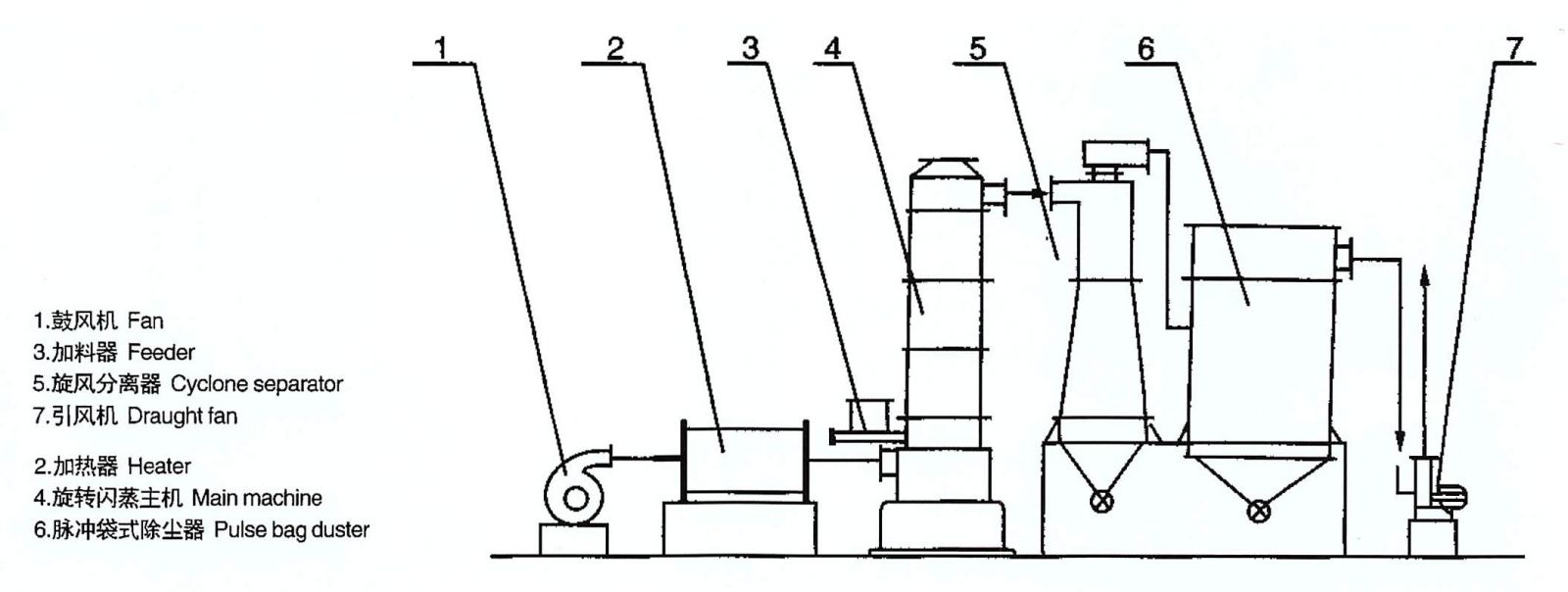

Technological process:

Features:

● Because the material is centrifugal, shear, collision, friction and micro-granulation, was highly dispersed state and the relative speed between the two phases of solid gas, enhanced the mass transfer heat transfer, so the machine production of high strength.

● Dry gas into the bottom of the Drying machine, resulting in a strong rotating air flow, the material on the wall of a strong scouring with a role in the elimination of sticky wall phenomenon.

● In the high temperature area of the bottom of the Drying machine, the heat-sensitive material is not in direct contact with the hot surface and is equipped with special equipment to solve the problem of coking discoloration of the heat-sensitive materials.

● Due to the high speed of the indoor air in the drying chamber, the material residence time is short, which is high efficiency, fast, small equipment and large production.

● The upper part of the drying chamber is equipped with ceramic ring and swirl plate, which can control the particle size and humidity of the export logistics to meet the final grain size requirements of different materials.

Applications:

● inorganic: boric acid, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydroxides, all kinds of heavy metal salts, synthetic cryolite;

● organic matter: Atrazine (pesticide pesticides), lauric acid, benzoic acid, benzoic acid, sterilization Dan, sodium oxalate, cellulose acetate;

● Ceramics: kaolin, silica, clay, etc .;

● Dye: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various azo dyes intermediates.

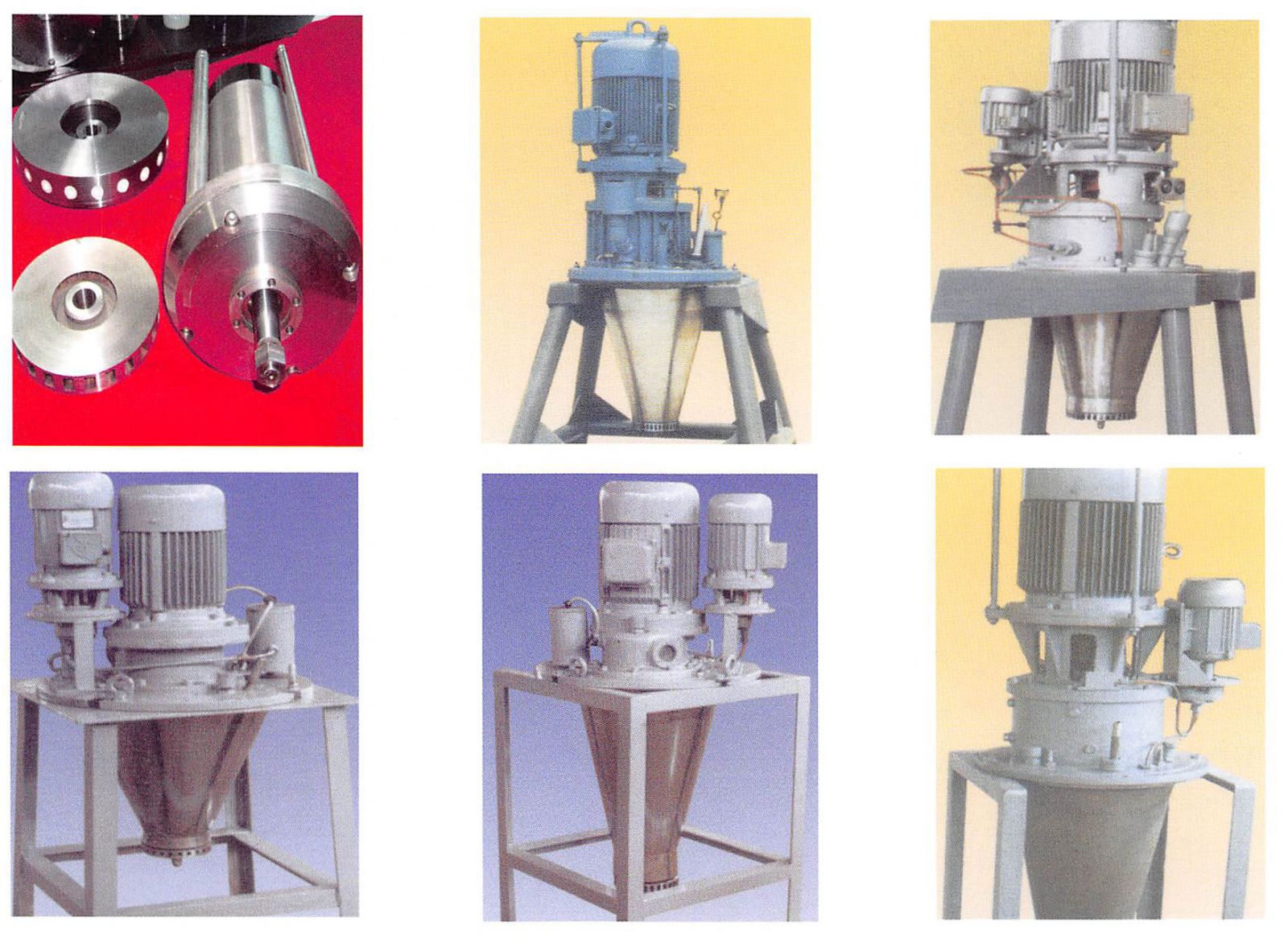

Performance Parameters of WHQ series High - speed centrifugal atomizer

| Atomizer model |

Fog plate diameter (Mm) |

Maximum speed (R / min) |

Maximum spray volume (Kg / h) |

Motor Power (Kw) |

|

| WHQ-10 | φ50 | 30000 | 10 | 0.75 | |

| WHQ-20 | φ80 | 24000 | 20 | 1.1 | |

| WHQ-50 | φ100 | 22000 | 50 | 1.5 | |

| WHQ-100 | φ120 | 20000 | 100 | 2.2 | |

| WHQ-200 | φ135 | 18000 | 200 | 3 | |

| WHQ-300 | φ150 | 17000 | 300 | 4 | |

| WHQ-500 | φ150 | 16000 | 500 | 5.5 | |

| WHQ-1000 | φ180 | 13000 | 1000 | 7.5 11 | |

| WHQ-4000 | φ210 | 12000 | 4000 | 15 22 37 | |

| WHQ-8000 | φ240 | 10000 | 8000 | 45 55 | |

| WHQ-12000 | φ260 | 9000 | 12000 | 75 | |

| WHQ-15000 | φ280 | 8000 | 15000 | 90 | |

| WHQ-18000 | φ300 | 7500 | 18000 | 110 | |