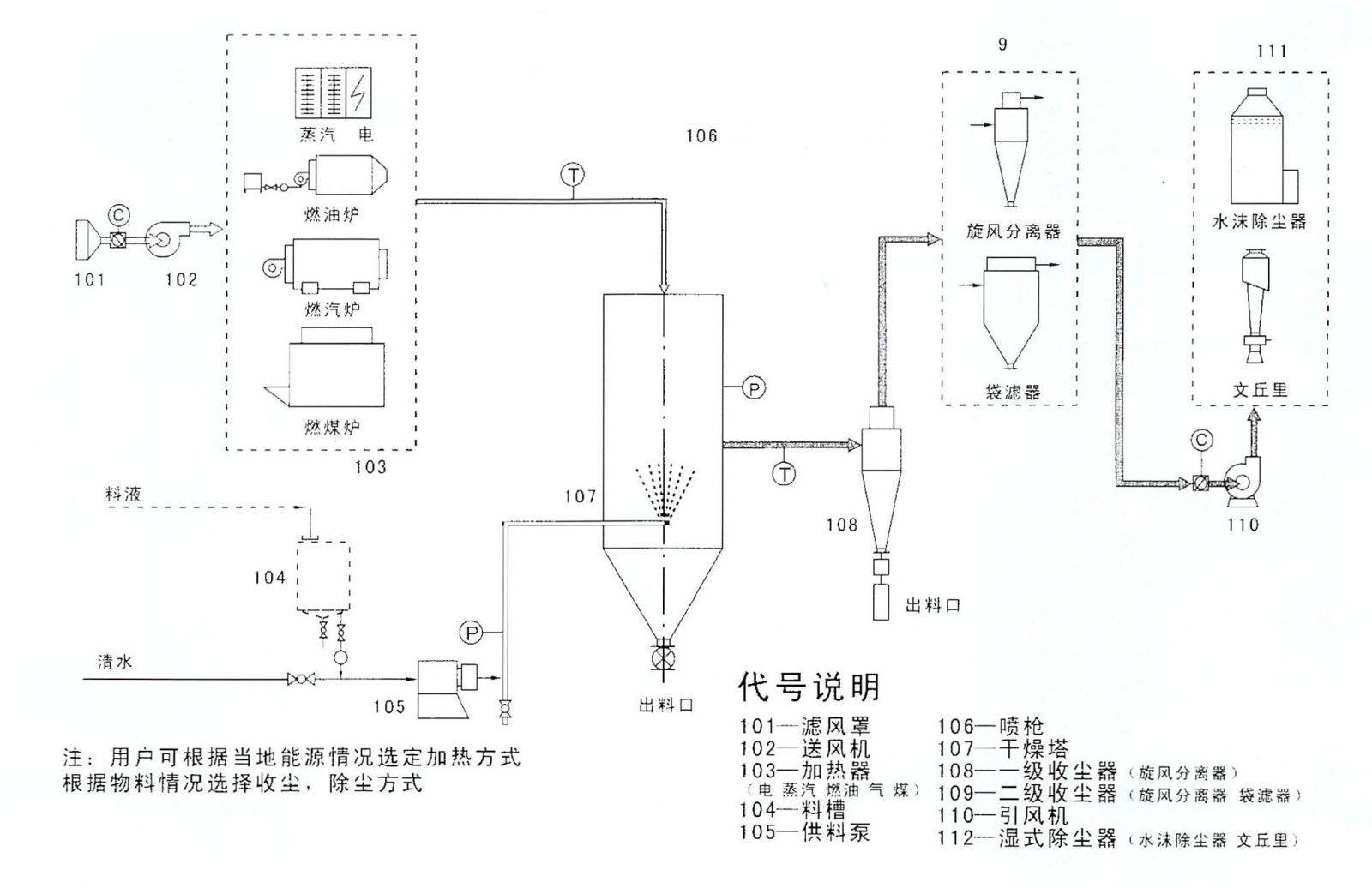

Working principle:

Working principle:

The air enters the heater through the filter, exchanges hot air into the hot air distributor at the top of the drying chamber, and the air is evenly rotated into the drying chamber. The liquid is filtered and pumped from the high pressure to the nozzle located in the middle of the drying chamber. The material is physically soiled, so that the surface area of the liquid material is greatly increased, and the hot air meets in contact, so that the water evaporates rapidly. In a very short time Drying of Granules Most of the finished product is collected by the bottom of the tower at the outlet, and the exhaust gas is discharged from the exhaust fan.

Features:

● fast drying, especially for heat-sensitive materials.

● The product is spherical particles, uniform material, fluidity, good solubility. Product high purity, good quality.

● Use a wide range, can be hot air drying, granulation, can also be used for spray concentration, spray crystal, spray reaction.

● can be equipped with fine powder to send back, and then wet agglomeration system to meet the user's material size requirements. The use of mixed-pressure dry granulation, the user can adjust the size of their products according to their needs, to adjust the amount of liquid spray and nozzle diameter and liquid concentration or appropriate process of processing additives to achieve the required particle size requirements.

● The machine is usually used for solid content of 40-70% of the liquid for spray, one-time to become a granular product, most of the materials collected by the spray dried products no longer need to be crushed and screened, both to simplify the production Technological process , But also reduces the production process to ensure the purity of finished products.

● After drying the product has good dispersion, mobility and solubility, for the product size, feeding density and water within a certain range, change the operating conditions, can be adjusted, production management sequence of operation convenience.

Applications:

This series spray drying machine is mainly used in chemical, metallurgy, electronics, ceramics, mining, pesticides, dyes, pigments, detergents, waste water treatment and other industries in a variety of emulsions, suspensions, pastes and aqueous materials dry.

Technical Parameters:

| Project / model |

YPG-6 | YPG-12.5 | YPG-25 | YPG-50 | YPG-65 | YPG-100 | YPG-200 | YPG-300 | YPG-500 | YPG-800 | YPG-1000 | YPG-2000 | YPG-3000 |

| Water evaporation (kg / h) |

6 | 12.5 | 25 | 50 | 65 | 100 | 200 | 300 | 500 | 800 | 1000 | 1200 | 3000 |

| Spray form |

Low pressure pressure spray |

||||||||||||

| Spray pressure (mpa) |

DYP series 0.6-4.0 (PLP series 2.5-15) | ||||||||||||

| Tower diameter (mm) |

1540 | 1750 | 2200 | 3000 | 3200 | 4200 | 4700 | 5400 | 5600 | 5800 | 6200 | 6800 | 7500 |

| Height of tower body (mm) |

5200 | 6300 | 7650 | 9400 | 9400 | 11250 | 14500 | 15850 | 16000 | 18000 | 18500 | 20000 | 23000 |

| Land length (mm) |

3000 | 3800 | 5000 | 5400 | 5600 | 9000 | 10000 | 13000 | 15000 | 17000 | 17500 | 17500 | 2000 |

| Area width (mm) |

2000 | 2750 | 4200 | 4700 | 4900 | 6500 | 7000 | 8500 | 10000 | 12000 | 12500 | 13000 | 17500 |

| Note: The amount of water evaporation and material properties, including solid and hot air import and export temperature. |

|||||||||||||

Technological process:

Heating method: